Transparency from label to wardrobe

Digital Product Passport in the Textile Industry

The textile sector is among the first where the European Union will mandate the Digital Product Passport (DPP). The reason lies in fashion and clothing's significant environmental pressure – excessive use of raw materials and water, short product lifespans, and extremely low reuse and recycling rates.

Regulatory Framework and Requirements

Digital Product Passport for Textiles

Steps for DPP Implementation

Product creation at the factory

At the design and production stage, data on the fabrics, fibres and dyes used is entered, along with information on the origin of raw materials.

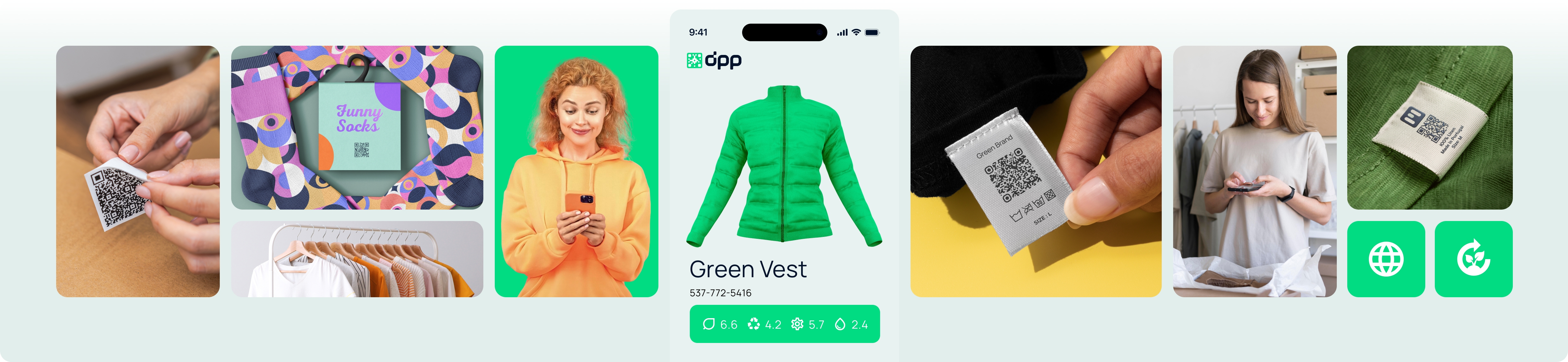

Generating a Digital Product Passport

For each batch of clothing or individual item, a unique DPP is created as a QR code or link, containing information about materials, manufacturing processes and sustainability metrics.

Supply chain integration

Garment factories, fabric suppliers and wholesalers add data on transport, storage and certifications such as OEKO-TEX or GOTS.

Access for retailers and service centres

Retailers and boutiques receive data on collections, sizes and product characteristics. Service centres have access to repair, alteration and recycling guidelines.

Access for end consumers

Via a QR code, customers can view details about the garment's composition, washing and care instructions, as well as information on its sustainable production.

Post-use tracking

When returned or collected for recycling, the passport is updated to record reuse, material transformation, or integration into a new production cycle.

WIARA offers a ready-made and easy solution

DPP

Frequently Asked Questions

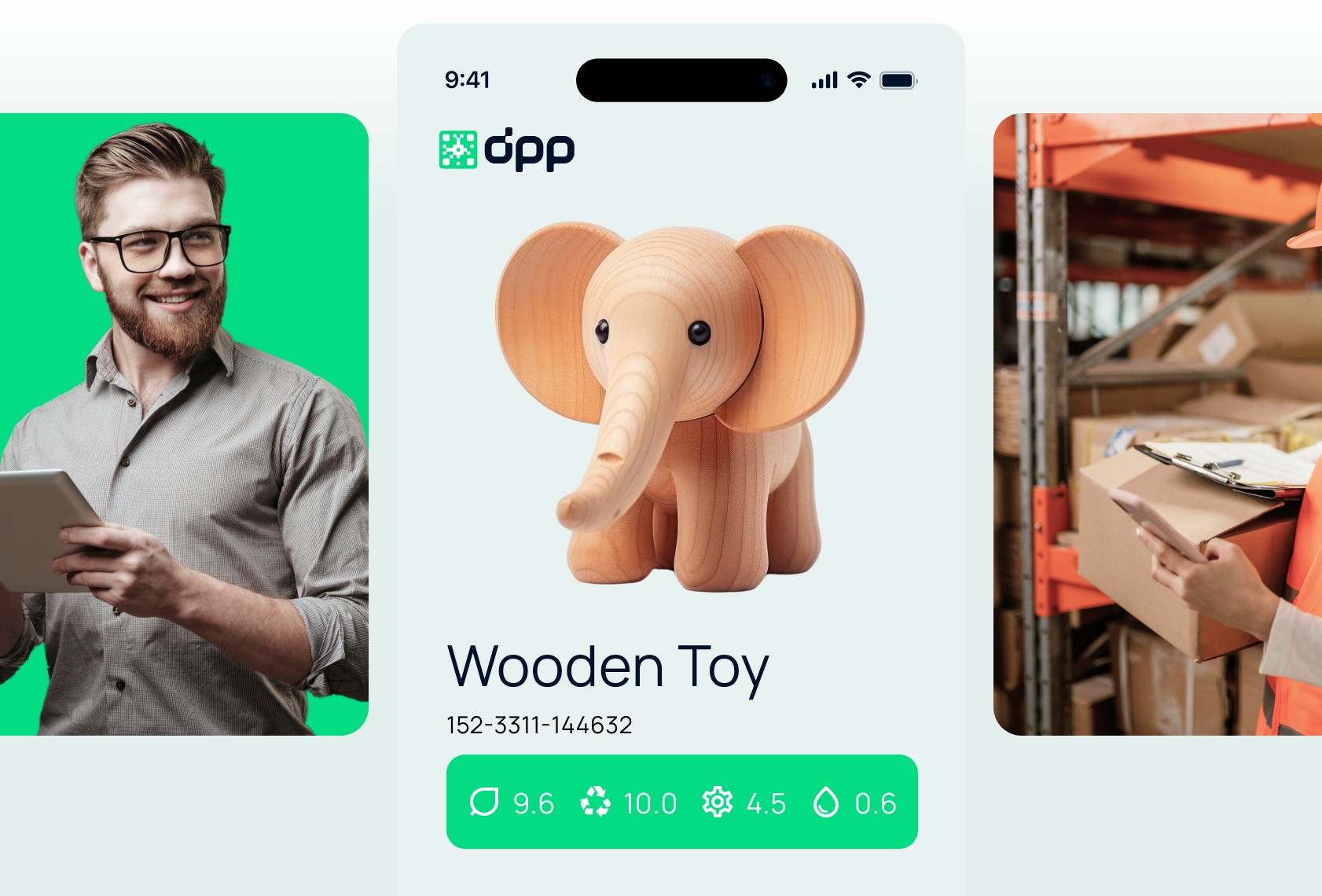

Data on material composition, fibre origin, chemical usage, carbon footprint, repairability, recyclability, and end-of-life treatment instructions – of particular importance for manufacturers and distributors.

Through a QR code or other electronic carrier attached to each textile product.

Manufacturers will demonstrate transparency, comply with EU requirements, and build trust with their customers and international partners.

They will receive clear information about product sustainability and quality, as well as guidance on proper care and recycling – helping consumers make informed choices.

It will require stricter tracking of materials and processes, improving transparency and reducing the grey market, including in textile production and imports.

The biggest challenges involve digitising data, integrating new systems, and collecting reliable information from suppliers – a key step for producers and exporters.

Transparency Everywhere

Related Industries and Solutions

DPP for End Consumers

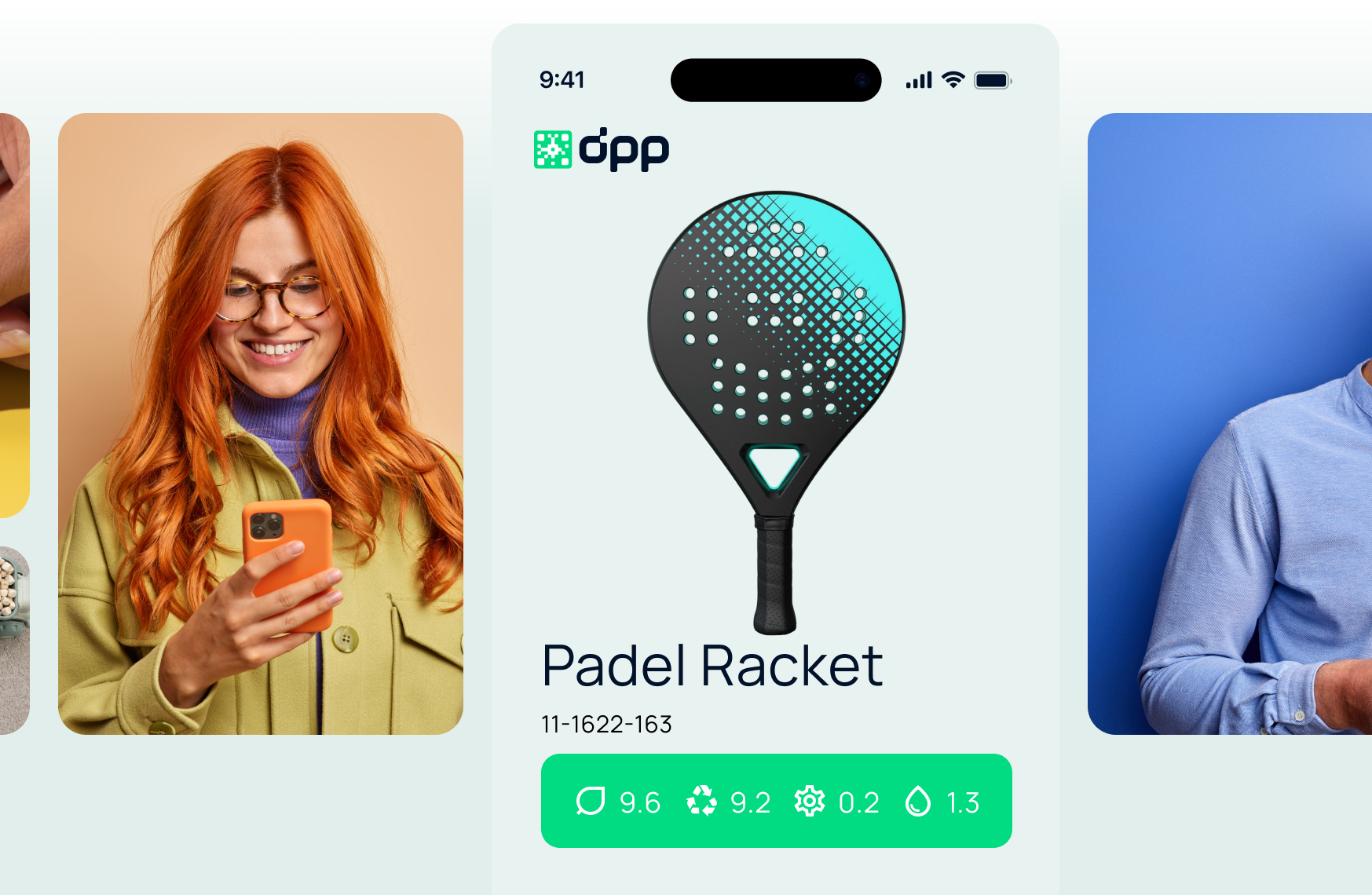

DPP provides transparency – composition, origin and recycling of products, so consumers can choose responsibly and make informed decisions.

DPP for Retailers and Service Centres

DPP simplifies warranties, repairs and product tracking. Retailers and service centres receive accurate information for higher quality service.

DPP for Importers

Importers ensure a valid DPP for every product and provide EU market access without risk of sanctions and delays.

Get Started

Schedule a meetingHome

About Us

ESPR - Core Framework

DPP - Digital Product Passport

Work Plan 2025-2030

DPP - First Affected Industries

© 2026 WIARA DAAS Ltd.

All rights reserved.